Australian Panels is committed to on-going reviews of its Safety Data Sheets and enviromental certification to ensure they reflect all current information. Below are a list of Safety Data Sheets and certification documents available for download.

-

RECYCLING

53,000 +

solar panels

across facilities10,500 tonnes +

CO2 emission

reduction per year10 MW Solar PV

Oberon’s rooftop

solar system is the

largest in Australia

Australian Panels has various recycling efforts in place, reducing carbon emissions and diverting waste from landfill. Significantly, Australian Panels have been investing in solar power since 2018. Over the last 2 years the company has installed over 53,000 solar panels across its network of facilities, thereby becoming more energy efficient and avoiding 10,500 tonnes of Co2 emissions per year. This is further supported by an internal fleet department, maintaining and upgrading company vehicles to reduce overall emissions.

The collection of dust, bark and waste biomass produces fuel to power manufacturing plants, whilst MDF board offcuts are repurposed into pallets and bearers to generate packaging from waste materials. A 4-Megawatt Gas Turbine Generator was installed in 2020 and the 10 Megawatt rooftop solar system at Australian Panels' Oberon facility, supports the site's power consumption.

-

WOOD WASTE RECYCLING INITIATIVE

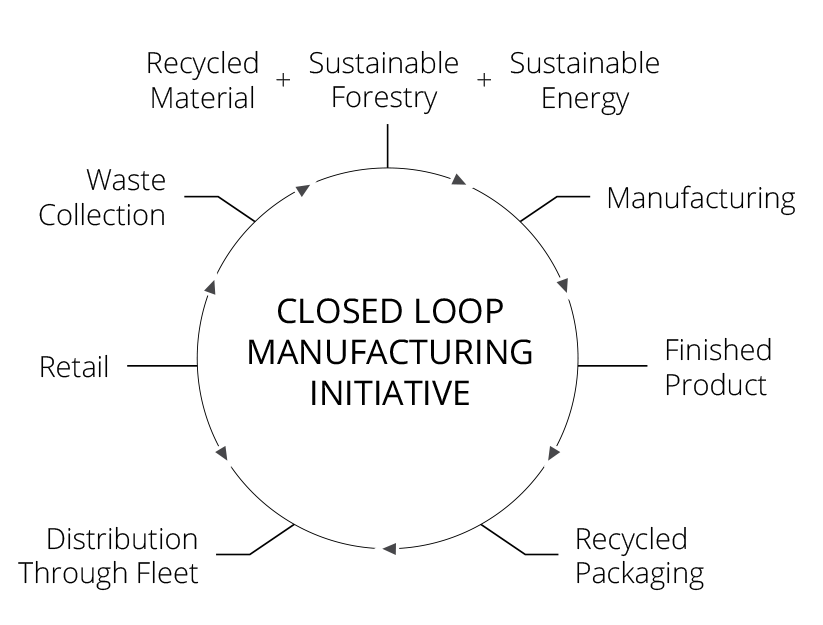

reDirect Wood Recycling has been established to provide a closed loop particleboard and wood recycling service. By installing a reDirect Recycling service you will enjoy significant cost savings in landfill charges. The reDirect Wood Recovery Initiative has been designed to service polytec customers who are buying raw and melamine coated particleboard products. reDirect Wood Recycling will reclaim materials that would otherwise go to landfill, thereby reducing waste, preserving plantation pine forests and protecting the environment for future generations. The manufacturing of particleboard utilises recycled wood and off cuts in the production of new particleboard. By opting for wood off cut collection through reDirect Recycling you are assisting in creating sustainable manufacturing practices.

-

CLOSING THE LOOP

A closed-loop manufacturing initiative creates an industrial ecosystem, in which the reuse of wastes or by-products is essential. Utilising the by- product of any process is an important part of sustainability—one such instance is the collection of waste water from the chip process, which is used to create steam for energy. Australian Panels aims to optimize the life cycle of manufactured products, eliminating unnecessary landfill while increasing the company’s social and environmental benefits. By adopting practices that influence product design and operational principles, the environmental impact will lessen over the entire lifespan of the product; this assists in the process of repurpose and re-manufacturing.

- REPORTS

- CERTIFICATION